Indoor Air Quality and Mold Prevention within a Building Envelope

Indoor Air Quality and Mold Prevention within a Building Envelope

Water entry at Mullions, window sills and window jambs

INTRODUCTION

WITHIN THIS PAGE

- Introduction

- Description

- Fundamentals

- Application

- Emerging Issues

- Relevant Codes and Standards

- Additional Resources

Microbiological organisms, such as fungi and bacteria, are important components of our ecosystem. These microorganisms break down dead material into its constituent components and as such are important participants in earth’s continuing life cycle. However, if these microorganisms proliferate in buildings, they can adversely impact indoor air quality (IAQ), create hazardous health conditions for the occupants and contribute to the deterioration of building components.

Moisture in envelope assemblies can cause numerous problems affecting the IAQ of a building and the longevity of building components. If elevated moisture levels persist on or inside a wall or roof assembly, these can lead to the growth of microorganisms such as mold and bacteria, as well as infestation by insects. The metabolism of mold and bacteria can create microbiological volatile organic compounds (MVOCs) that adversely affect air quality inside the building. Musty smells in a damp building typically result from these MVOCs. Spores or cellular components are allergens and if released into the building environment can cause physical symptoms and health effects. These organisms can also generate toxins that can cause health problems. Internal moisture degradation is a leading cause of premature failure of building envelopes. Persistent moisture can lead to rot, corrosion and other forms of deterioration. Moisture induced degradation could include reduced thermal resistance and decrease in the strength and/or stiffness of materials. Moisture also supports insect infestation, ranging from mites, which are too small to be seen by the naked eye, to cockroaches and ants. Insect infestation can result in the release of fecal material and insect parts into the building environment. Moisture travelling through building components can cause corrosion of components and dissolve water soluble constituents damaging structures, i.e. gypsum drywall and mortar in masonry construction.

Building materials and construction methods have changed over time from labour intensive un-insulated assemblies of natural materials to labour efficient assemblies of engineered products that result in more comfortable and highly energy efficient buildings. Current construction is much more air tight and highly insulated than those of old. Unfortunately, in terms of resistance to moisture damage this higher performance comes with a price. Current construction is less forgiving of shortfalls of design and construction than were those of the past. Current buildings are tighter and better insulated so they are able to maintain draft free environments with comfortable levels of temperature and humidity. The ability to maintain comfortable levels of temperature and humidity inside buildings increases the psychometric stresses driving moisture into the building envelope. Any defect in modern assemblies results in a large impact as present day construction has less moisture storage capacity than those of the past. Also, the high-performance engineered building materials in current use include hydrocarbon based materials such as paper and resins that are subject to attack by mold and bacteria.

Figure 1. Wall Construction from the 1800’s, 1932, and today

Figure 1 shows bearing wall construction common in the 1800s, masonry curtain wall construction from the 1930s and current construction using metal studs. The construction of bygone eras included masses of masonry that could store moisture impacting the wall. Current construction provides an air tight insulated envelope, but has little moisture storage capacity.

Table 1: Water Storage per Square Foot of Wall

| Stone and Brick Bearing Wall | 3.5 #/sq. ft. |

| Brick and Block Curtain Wall | 2.1 #/sq. ft. |

| Brick and Insulated Metal Studs | 0.5 #/sq. ft. |

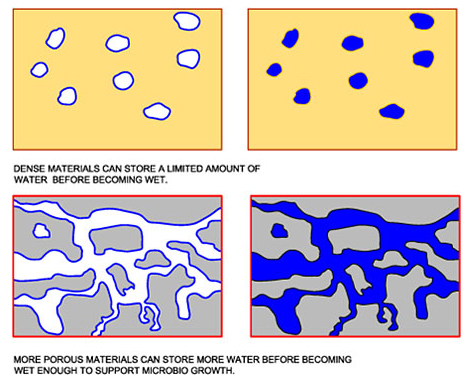

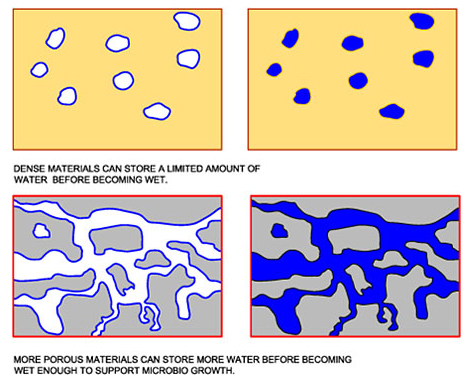

Table 1 gives the quantity of moisture that can be stored by each wall assembly before the surface moisture reaches the 70% that can result in mold and bacteria growth. Moisture can move through building envelopes as liquid water, water vapour or be carried by air infiltration. The passage of water vapour is slowed by materials that are relatively impermeable. These materials such as sheet plastic, asphaltic coatings and foil are called vapour retarders. Air barriers slow infiltration. Vapour retarders and air barriers must be carefully located within an assembly for an envelope to successfully deal with moisture migration. The way that moisture moves through a building assembly is complicated enough that the use of rules of thumb to determine the location of vapour retarders and air barriers is not recommended. An improperly located vapour retarder can cause condensation within cavities. The best way of predicting the performance of a building envelope is with a computer simulation. One of the more highly regarded programs for this is WUFI. (WUFI is a hygrothermal modelling program distributed by Oak Ridge National Laboratory ORNL. See end references.)

Table 2: Moisture Conditions for Albany, NY

| STORED WATER | MAX RELATIVE. HUMIDITY | LOCATION OF DAMP SURFACE | |

|---|---|---|---|

| Stone and Brick Bearing Wall | 1.63 lbs/ft³ | 65% | None |

| Brick and Block Curtain Wall | 1.63 lbs/ft³ | 67% | None |

| Brick and Insulated Metal Studs | 0.39 lbs/ft³ | >95% | At face of sheathing |

Results of Year Long Simulation by WUFI Pro 3.3

As can be seen from Table 2 construction of bygone eras did not develop moisture problems even without vapour retarders. However, sufficient moisture would collect inside a modern wall to support mold and bacteria just from diffusion of water vapour. Additional investigation demonstrated that installation of a vapour retarder on the inside of this wall alleviates the problem. However, if this wall were built in a hot humid climate the vapour retarder would need to be on the outside of the wall. In general a vapour retarder should only be placed on the warm side of the insulation layer. A vapour retarder on the cold side of the insulation (outside in cold climates, inside in hot humid climates) is likely to cause condensation within the envelope assembly. The problem is that large portions of the country have both a heating and a cooling season. If a vapour retarder is to be incorporated into a wall in this situation it is best to perform a computer simulation to determine the correct location. It is clear that it is critical that the design of modern envelope assemblies carefully consider the location of vapour retarders.

DESCRIPTION

MOLD

Mold requires a nutrient source, proper temperature and moisture to grow. Mold does not require light to grow. Mold is a saprobe meaning that it lives on dead organic materials. It does not produce food, but instead adsorbs nutrients by breaking down hydrocarbons. As such it will grow on any organic building material such as paper, adhesives, resins, etc. It will even grow on the patina of dust that collects on surfaces. The dust in office buildings consists primarily of paper dust and skin cells so that it provides an adequate nutrient source for mold growth. Nutrients to support mold growth are ubiquitous in the building environment. The temperatures required for mold growth are in the same range as indoor building environments. The pervasive nature of nutrients and a temperature range suitable for mold growth leave control of moisture as the only practical way to control mold growth.

Figure 2. Mold Need a Nutrient Source, Proper Temperature and Water to Grow

BACTERIA

Bacteria found in indoor environments typically come from human sources (skin and respiration) or from the outdoors. Like mold, most of the bacteria found in the air in buildings are saprobes, meaning they grow on dead organic matter. As far as building envelopes are concerned the primary concern is about bacteria colonies that may grow in damp areas.

INDOOR AIR QUALITY

In the process of digesting materials mold releases enzymes to break down complex hydrocarbons into glucose which it can absorb. During this process it produces metabolites which in turn produce MVOCs. MVOCs from mold can produce a musty odor; those from bacteria can produce a putrid odor. In addition microbiological growth can introduce spores and cellular debris into the building environment. As such, microbiological growth in buildings can adversely affect indoor air quality, lead to health complaints, and cause disease. This generally occurs when there is an abnormal amount of moisture in building components allowing the development of growing colonies of mold or bacteria. As mold and bacteria are ubiquitous in the environment this situation is referred to as amplification.

Figure 3. Mold Gives Off Spores, Cellular Debris and MVOCs

Microbiological Volatile Organic Compounds (VOCs): During metabolism mold and bacteria create microbiological volatile organic compounds (MVOCs). These are organic compounds that are in a gaseous state within the air of a building. Because they are in this gaseous state they can quickly disseminate throughout a building, even through building components such as wall assemblies. Many of these compounds have a low odor threshold and produce a musty or putrid odor that is quickly detected by occupants. MVOCs from mold and bacteria are obnoxious and can cause complaints about indoor air quality even in low concentrations. However, these appear to be mostly nuisance compounds and are not well linked to actual health effects.

Spores and Cellular Debris: Mold releases spores into the air as a means of reproduction. In addition cellular debris, such as cell wall material, can be released into the building environment from amplification sites. Spores and cellular debris are micro-particulates and, as such, can remain airborne for considerable periods of time travelling freely through tiny cracks, crevices, and holes in building walls, and roofs. Spores, and cellular debris from mold, are allergens and result in reports of symptoms, i.e. itchy eyes, runny noses, headaches, and fatigue. The responses to these allergens differ from person to person so that neighbouring building occupants may report very different reactions to mold amplification. Cellular debris from bacteria contains endotoxins which can produce allergic symptoms. At high levels, this material is an irritant and can produce flu-like symptoms. Spores and cellular debris can remain an indoor air quality problem even after active growth of an amplification site is corrected.

Toxins: Mold and bacteria both produce toxins as by products of metabolism. Some molds, under some circumstances, produce mycotoxins. Bacteria can produce exotoxins, which are secreted in the environment and endotoxins, as part of cell walls. Some of these are powerful toxins. In general, these compounds consist of large organic molecules that do not diffuse through the air in the same manner as MVOCs. They are found in the air when carried by contaminated dust, debris, spores, or cellular material. This means that exposure to these toxins are most likely when an amplification site is disturbed. Adverse health reactions to mycotoxins from molds such as Stachybotrys Chartarum, have been suspected in buildings with extensive mold growth, but so far have not been documented as a health problem in buildings.

DETERIORATION OF BUILDING COMPONENTS

Rot is the result of a fungal infection of wood and wood products. Wood consists of cellulose and a complex hydrocarbon called lignin. The rot fungus can attack either the cellulose or lignin. If it attacks the cellulose the brown lignin is left and brown rot is the result. If the lignin is attacked the white cellulose is left producing white rot. In addition there is a rot process produced by a fungus Poria. This fungus can start in moist soil and send rhizomes great distances through wood structures.

Figure 4. Examples of Wood Rot — White Rot, Brown Rot, and Poria

Nutrients: Mold and bacteria live on hydrocarbon based, organic materials. In buildings there are abundant organic materials such as wood, wood products, paper, adhesives, and glues. Even in the absence of organic building materials, dust and dirt, which collect on surfaces in buildings, are primarily organic and can, in the presence of water, readily support mold growth. Specific building materials that can support this growth include:

- Paper products, i.e. the paper on gypsum panels used for drywall, facing for insulation, wall coverings, etc.

- Wood and wood products including dimensional lumber, plywood, oriented strand board, and particle board.

- Resins and adhesives. For example, the resin that binds glass fibres together to form fibre glass board insulation can provide food for mold growth unless treated with a biocide.

- Glue such as wallpaper paste

- Oily surfaces

The dust that collects in office buildings is primarily paper dust, skin flakes, and fibres from carpeting and clothing. This dust will support mold growth. Basically, the food sources for mold are ubiquitous and attempts to control microbiological growth by limiting the food source is generally not successful.

Temperature: The temperatures routinely maintained in buildings and found in building envelopes are within the range that supports the growth of a wide range of molds and bacteria. Most molds grow in the temperature range of 15° to 30° C (59° to 87° F). Most bacteria found in the air in buildings grow in a temperature range of 18° to 30° C (62° to 87° F) for environmental bacteria and 35° to 44° C (93° to 113° F) for human source bacteria.

MOISTURE REQUIREMENTS FOR MICROBIOLOGICAL GROWTH

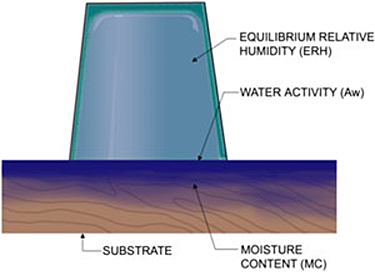

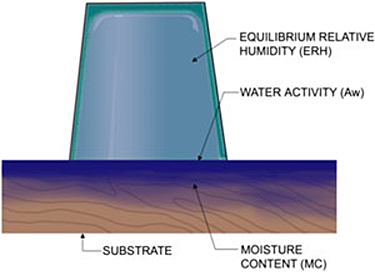

Mold and bacteria require a relatively moist surface in order to grow in sufficient quantities to cause indoor air quality problems. The moisture requirements for mold growth are expressed in terms of Active Water (Aw). However, field measurements of moisture content are in terms of Equilibrium Relative Humidity (ERH) or Moisture Content (MC).

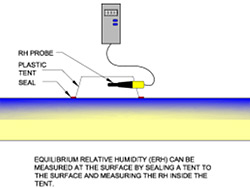

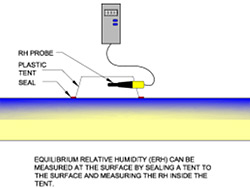

Figure 5. Moisture and Mold: The Moisture Content (MC) of a substrate results in water at the surface described in terms of Water Activity (Aw) by mycologists describing the moisture requirements for mold growth. Water activity of a surface is measured in the field by sealing a vessel to the surface and measuring the humidity of the trapped air once it comes into equilibrium with the surface. This is called equilibrium relative humidity (ERH).

Water Activity (Aw): Mycologists measure the moisture requirements for mold growth in terms of Water Activity (Aw). This is a measure of the amount of moisture that is available to support microbiological growth. Water Activity is the water vapour pressure of the amount of water in a material relative to the water vapour pressure of pure water expressed as a ratio. For example, if the vapour pressure of the water in a material is 70% of pure water (or the saturated material) the Aw will be 0.7. This is essentially a measure of the moisture content of the material at its surface relative to the maximum amount of water it is able to retain when saturated. As a practical matter Aw is measured by placing the material in a sealed chamber, allowing the air in the chamber to reach moisture equilibrium with the material, and then measuring the relative humidity and multiplying by 100 to get the ratio.

Equilibrium Relative Humidity (ERH): Relative Humidity (RH) is the vapour pressure of the water vapour in the air relative to the vapour pressure of the air when it is saturated (holding as much water vapour as it can—this would be the vapour pressure of air in equilibrium with a surface of water). This is expressed as a percent. For example, if the vapour pressure of the water vapour in the air is 70% of the saturated vapour pressure then the relative humidity is 70%. Equilibrium Relative Humidity (ERH) is the relative humidity that will be reached if a material is placed in a sealed chamber—air in the chamber is allowed to reach moisture equilibrium with the material, and then the relative humidity is measured. As can be seen this is the same as Aw except it is expressed as a percentage rather than a ratio. This gives a practical method of measuring Aw in the field. A dome or sheet of plastic can be sealed to a surface, the contained air allowed to reach equilibrium with the surface, and then the ERH is directly measured.

Moisture Content (MC): Moisture Content (MC) is the mass of the moisture in a material relative to the dry mass of the material, expressed as a percent. For example if there is 17 grams of water in a piece of wood that weighs 100 grams when dry, then the wood has a Moisture Content (MC) of 17%.

MOISTURE REQUIREMENTS FOR MOLD GROWTH

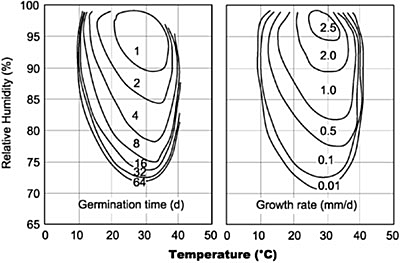

In general the more water that is present the faster that mold will germinate and the faster it will grow. Figure 6 gives the length of time it typically takes for mold to germinate as a function of moisture content and temperature (this sort of plot is called an isopleth). As can be seen the more moist and warm a material the more quickly a mold problem can develop. Mold will germinate on a material with an Equilibrium Relative Humidity (ERH) of 90% and temperature of 30°C within a day. This could happen inside a sun warmed wall. If the temperature is reduced to a typical indoor temperature of 20°C the germination time goes to 2 days. If the material is wetted and then begins to dry out so that the ERH drops below 90% then the germination time increases. These are germination times for mold growing on an ideal food source such as agar. Experience with Florida hurricanes and recent research with drywall panels indicates that may take as long as two weeks for visible mold colonies to appear on wetted building materials.

Figure 6. Isopleths of Mold Germination and Growth rate: As can be seen the wetter a surface the quicker mold spores will germinate and the quicker they will grow. Typical room temperatures of 21° C are about ideal for mold growth.

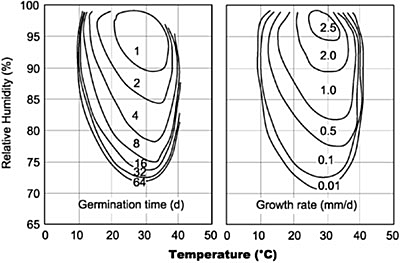

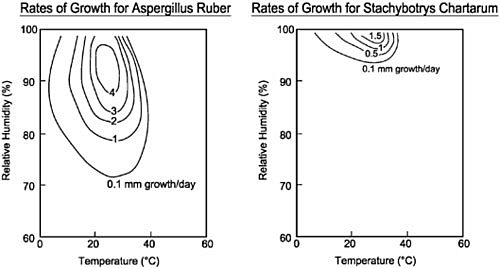

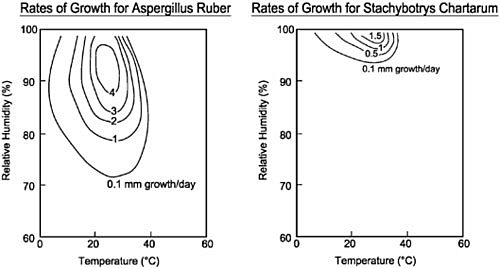

Mold is classified according to the amount of water required for growth (see table 5). However, most molds regardless of classification will grow best with an Aw of 0.90 (ERH of 90%) or better. Mesophilic molds are sometimes referred to as primary colonisers as they will grow under lower moisture conditions and are frequently the first types of mold that are discovered during the early stages of a moisture problem such as windows that leak under a driving rain. The mold is able to survive under conditions of periodic wetting with moisture levels dropping between episodes as surfaces dry. As the situation becomes more severe and wetting is more continuous Hydrophilic fungi such as Stachybotrys spp. will appear.

Figure 7. Isopleths for Aspergillus and Stachybotrys: As can be seen the mesophilic mold Aspergillus Ruber is able to start growth with an equilibrium relative humidity of just above 70%, while it requires an ERH greater than 90% for Stachybotrys Chartarum to grow.

MEASURING MOISTURE

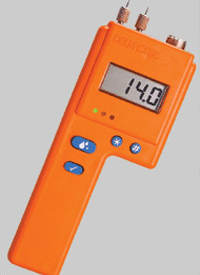

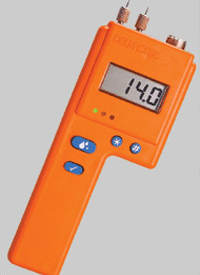

Moisture in building materials can be measured with direct reading instruments or by sealing a vessel over the surface and measuring the equilibrium relative humidity. Moisture surveys of buildings typically start with a qualitative sweep with a pinless type meter to determine patterns of moisture intrusion followed by a more precise measurement with a pin type meter. Equilibrium relative humidity measurements are typically performed on concrete to determine if it is dry enough to receive finishes.

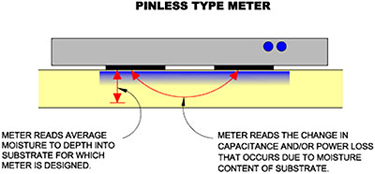

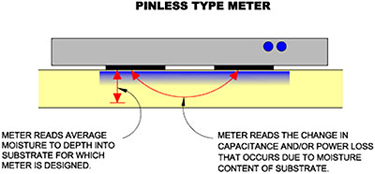

Pinless Meters: These direct read instruments have pads or sensors that measure the capacitance changes or power loss, in a surface, that occur with moisture saturation. They can be calibrated to provide a moisture content measurement, but are frequently used to quickly determine relative moisture levels without damaging a surface.

Figure 8. Diagram of the Operation of a Pinless Moisture Meter: Pinless moisture meters provide a measure of moisture in a substrate without making holes in the surface.

Figure 9. A Typical Pinless Moisture Meter

Figure 10. Using a Pinless Meter to Map Damp Area: The pinless meter allows damp areas to be quickly mapped out.

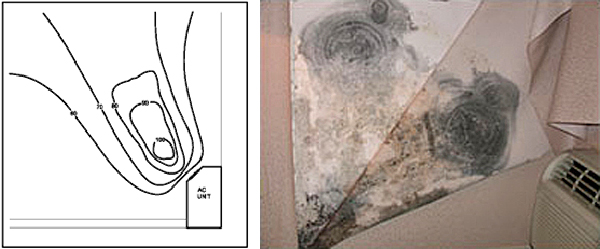

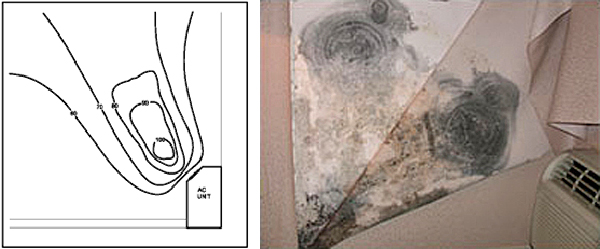

Figure 11. Condensation Caused by AC Unit Chilling a Wall: The mold in the photo on the right was caused by the pattern of condensation mapped on the left.

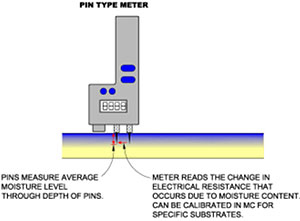

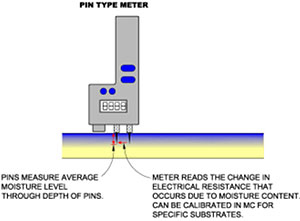

Pin Type Meter: These instruments have a pair of pins that are driven into the surface. The instrument measures the electrical resistance of the material between the pins. As moisture content increases the resistance of the material decreases. The meter is calibrated so that it determines the moisture content of the material relative to the electrical resistance measured by the pins. Each material has a base electrical resistance when dry. So the measurements are specific to the material being measured.

Figure 12. Pin Type Meter: The pins are jabbed into the surface to measure moisture.

Equilibrium Relative Humidity: The equilibrium relative humidity of a material can be measured by sealing a vessel to the surface and then measuring the relative humidity inside the vessel once equilibrium is established. Another method is to tape sheet plastic to a floor slab and observe the inside surface for moisture condensation. These methods are widely used to determine if a concrete floor is dry enough for the installation of floor finishes.

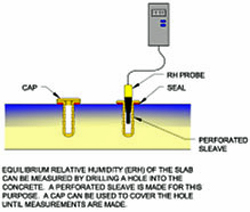

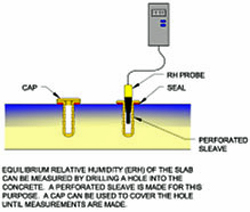

Figure 13. Measuring ERH of a Slab: A simple device can be made from a pipe fitting to measure ERH of slabs. The edge is sealed to the floor with plumber’s putty. If the air is at a different temperature than the slab a more accurate measurement results if the outside of the fitting is insulated.

Moisture Content of Concrete: The moisture content of the slab interior can be measured by drilling a hole, inserting a relative humidity probe and measuring the equilibrium humidity.

Figure 14. Measuring Moisture Content of a Slab: A plastic sleeve with knock out holes is sold for use in measuring moisture level in slabs. The holes are knocked out at the depth that is to be measured. A cap is provided to cover the sleeve and allow the slab to reach equilibrium. This avoids leaving the expensive RH probe where it can be damaged.

FUNDAMENTALS

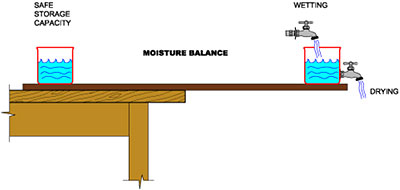

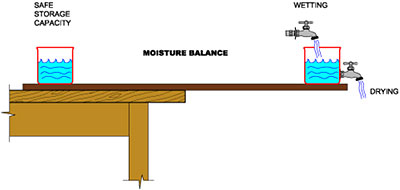

MOISTURE BALANCE

Moisture constantly enters building envelope components as liquid water, water vapor and infiltrating moist air. In addition the envelope may contain water that has been built in during construction. If designed properly, the envelope will also continually dry due to moisture transport out of the envelope. If the rate of introduced moisture exceeds the rate of drying the water content of envelope components increases. Many building materials have the capacity to safely store water. For example, wood is not considered to be wet until its moisture content exceeds 17%. If a building component takes on enough moisture to exceed its storage capacity it becomes damp and microbiological growth and rotting can occur.

Figure 15. Moisture Balance

Moisture enters and leaves envelope components. Mold growth and deterioration will be avoided as long as there is a balance between wetting and drying of the component so that the moisture storage capacity is not exceeded. Assemblies with a large amount of storage capacity such as massive masonry construction will be more forgiving of periodic wetting as a result of being able to store moisture. Modern construction generally has less storage capacity so that it is more sensitive to leaks.

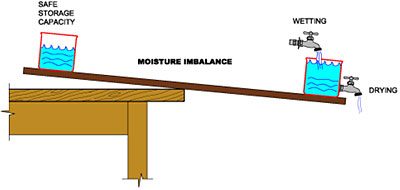

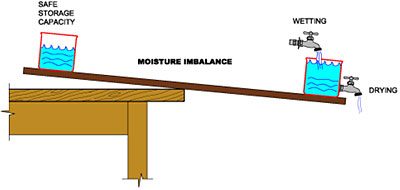

Figure 16. Moisture Uptake Exceeds Dryings

Once the rate of moisture uptake exceeds drying the envelope component takes on water. If the storage capacity of the material is exceeded it becomes wet and mold growth and deterioration may occur. The relatively small storage capacity of modern construction makes it important to restrict and control the amount of moisture that enters the envelope, and design envelopes so that they dry under the influence of natural forces.

Water in Building Materials: There are three (3) basic ways in which water is held in building materials.

- Bound Water: This is water that is mixed with certain building materials during construction and during the ‘drying out’ period evaporates into the internal environment of the building. If there is inadequate ventilation of the space, condensation can occur in the interstitial spaces of the exterior building envelope. The remaining water is set or ‘chemically bound’ within the building material.

- Absorbed Water: This is water that is absorbed directly from the air. The amount of water absorbed is dependent on the relative humidity or water vapour pressure of the ambient air and the hygroscopic properties of the building material.

- Capillary Water: This is liquid water that is ‘drawn in’ through the pores or capillaries of the building material. The amount of water absorbed is related to the porosity and the amount of liquid water available at the surface of the material. This water can come from driving rain, high water table, inadequate drainage, plumbing problems, or condensation.

Figure 17. Water Storage of Building Materials

Moisture Storage Capacity: Table 4 gives the safe moisture storage capacity of some typical building materials. This table has been extracted from a comprehensive database of materials included with the WUFI hygrothermal simulation software. The moisture storage capacity is defined as the amount of moisture a material can hold before the equilibrium relative humidity (ERH) at the surface reaches 70%.

Table 4: Moisture Storage Capacity of Building Materials

| WATER STORED AT 70% RELATIVE HUMIDITY (POUNDS/CUBIC FOOT) | |

|---|---|

| Concrete (B45) | 4.32 |

| Concrete Block (Pumice aggregate) | 0.96 |

| Fiber Glass | 0.00 |

| Gypsum Board | 0.38 |

| Gypsum Plaster | 0.09 |

| Softwood | 3.16 |

| Solid Brick Masonry | 0.61 |

| Steel Studs | 0.00 |

Construction Moisture: Moisture is incorporated into many materials during construction. For example concrete, masonry, drywall taping compound, and some paints all have water as a component. Construction moisture can equal or even exceed the safe moisture storage capacity of the material. This water must be able to escape from an assembly or moisture problems such as mold growth can occur. For water based coatings this can be a simple matter of maintaining environmental conditions favourable for drying for a period after application. In instances where a surface is to be covered with an impermeable covering or coating the substrate must be adequately dry prior to covering. Measurement of concrete moisture prior to application of resilient flooring is an example of this situation. In situations where a moisture laden component such as concrete or masonry is built into an assembly it may be necessary to allow the materials to dry before covering with other construction. Otherwise, the assembly must be put together so that construction moisture can escape.

Moisture Entry into Envelopes: Moisture can enter envelope assemblies as liquid water through leaks and capillary action, and as water vapour through infiltration of humid air and water vapour diffusion.

Liquid Water: Control of liquid water entry into envelope assemblies are discussed in the sections on specific envelope components. Given the inevitability of material failures and construction practice mistakes it is prudent to design building envelopes so that they are forgiving and dry out when water gets into them.

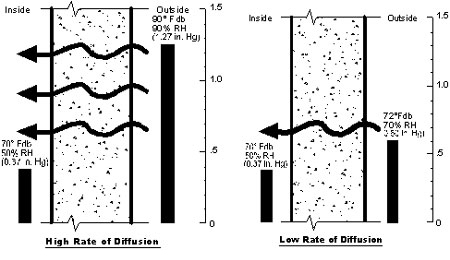

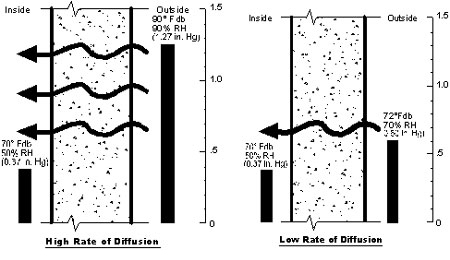

Water Vapour Diffusion: Water vapour in the air is a gas. As the temperature and relative humidity increases the vapour pressure of atmospheric water increases. This means that there will be a vapour drive from hot humid areas, where the vapour pressure is higher, toward areas that are cooler and dryer, where the vapour pressure is lower. If the building envelope were completely transparent to the moisture this would not be a problem. The water vapour would simply pass through the assembly. However, envelope assemblies are built with multiple layers of materials with different permeability to water vapour. Problems arise when the passage of water vapour is retarded at a layer that has been chilled to a sufficiently low temperature to condense liquid water. This can happen if a material, acting as a vapour retarder, that is located on the cool side of an assembly. For example, if vinyl wall covering is installed on the inside of a wall in an air conditioned building in a hot humid environment such as South Florida. This would constitute a misplaced vapour retarder, as it is on the cool side of the wall assembly. Water vapour is driven through the wall from the hot humid outside until it comes in contact with the wall covering where water vapour transmission is essentially stopped. In this instance, moisture is likely to condense in the glue layer holding the vinyl wall covering in place. Mold and bacteria are then able to amplify in the moist glue. The same thing can happen in a northern climate during the heating season if a vapour retarder is placed outside of the insulation under siding. As these examples illustrate it is very important to carefully consider the location of any materials that interrupt the smooth transmission of water vapour through building envelope assemblies When designing building envelopes (exterior walls and roofs) it is prudent to use a hygrothermal modelling program such as WUFI to assist in locating vapour retardant layers.

Figure 18. Vapour Diffusion through Walls: The greater the temperature and humidity difference from outside to inside the greater the vapour drive though the wall.

When it is hot and humid outside, a pressure differential is created as can be seen from Figure 18 above. This results in a vapor drive from outside toward the inside. If an impermeable finish such as vinyl wall covering were installed moisture would condense out on the back surface of the wall covering permitting mold growth in the adhesive holding the wall covering in place. In northern climates the vapour drive is from inside to outside during the cooling season. During periods of extreme cold this vapor drive can result in frost formation on the inside surface of plywood sheathing leading to wet insulation, mold growth and rotting.

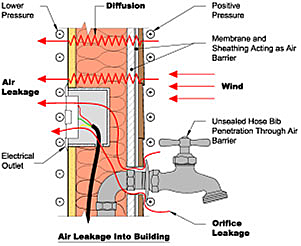

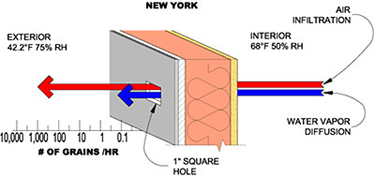

Air Infiltration: It is physically impossible to build envelope assemblies so that they completely prevent air infiltration and water vapor diffusion. Air infiltrates envelope assemblies driven by the pressure differential created by wind and stack effect.

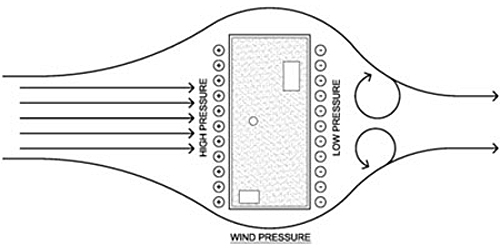

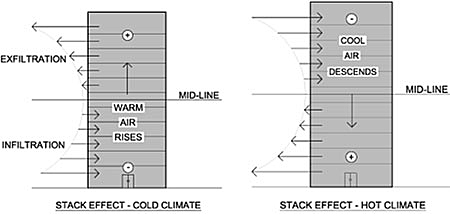

Figure 19. Wind Creates a Positive Pressure on the Windward Side of a Building and a Negative Pressure on the Lee Side

The wind creates a positive pressure on the windward side of the building and a negative pressure on the lee side. This forces air into the building on the windward side (infiltration) and sucks it out on the lee side (exfiltration).

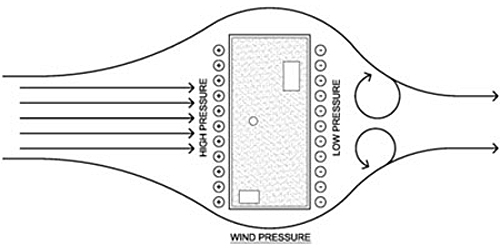

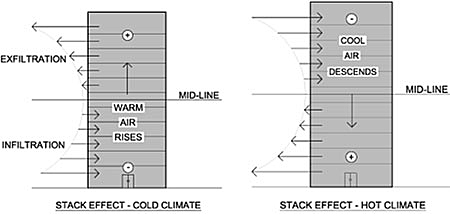

Figure 20. Stack Effect

In the winter warm air inside a building is buoyant relative to the more dense cold outside air. Just like hot smoke rising in a smoke stack, the warm air tends to rise through vertical shafts and floors in a high-rise building. As the building is functioning like a smoke stack this is referred to as the stack effect. As the warm air rises it creates a negative pressure in the lower half of the building and cold outside air infiltrates in to replace the rising warm air. The warm air creates a positive pressure in the top half of the building so that warm air exfiltrates out of the building. The same thing happens in reverse to high-rise buildings during the cooling season in hot climates.

Figure 21. Air Leakage Through Envelope Assemblies: Air is driven through any small opening into building envelope assemblies.

Building materials, to a greater or lesser degree, are porous enough, or assemblies contain sufficient seams and joints, that air is forced into the envelope assembly by the pressure differential. Air barriers limit the amount of air that is squeezed into the envelope assemblies, but cannot stop it completely. Air that enters the assembly from the outside in the summer or in hot humid climates carries moisture in the form of humidity. During the heating season warm moist air inside the building will be forced into the envelope assemblies.

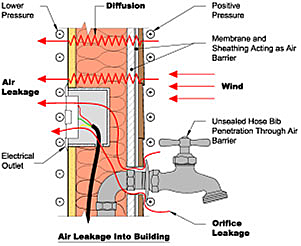

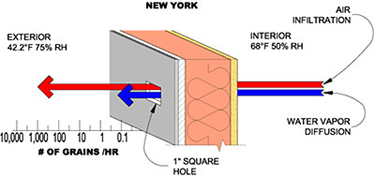

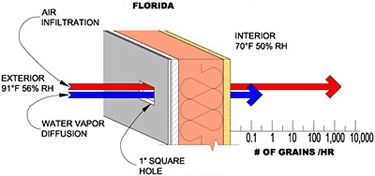

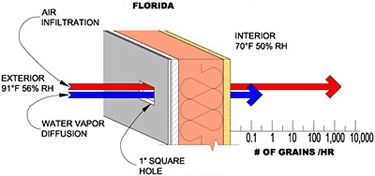

Air Infiltration vs. Water Vapor Diffusion: An opening in an envelope assembly will allow both air infiltration and water vapour diffusion to deliver moisture to the assembly. As can be seen from the diagrams below far more moisture is delivered into the assembly by air infiltration.

Figure 22. Air Infiltration and Water Vapour Diffusion During a Heating Season: Far more moisture is carried by infiltrating air than is transported by vapour diffusion.

Figure 23. Air Infiltration and Water Vapour Diffusion During a Cooling Season: Far more moisture is carried by infiltrating air than is transported by vapour diffusion.

APPLICATION

Drying of Envelope Assemblies: Moisture inside building envelope assemblies will create a vapour pressure inside the assembly. If there is nothing to impede the transmission of water vapour on the cool, dry side of the assembly then water vapour will migrate from the assembly towards that environment. In air conditioned buildings it becomes part of the cooling load, in heated building it passes outdoors. This allows water to escape from the assembly and allows the assembly to dry.

Design of Forgiving Envelope Assemblies: First, envelopes must be designed to prevent the entry of liquid water into the envelope assembly. The means for accomplishing this are discussed in other parts of this page. The portions of exterior walls that are acting as a rain screen should be designed so that they are sufficiently well ventilated that they dry between rain events.

The building envelope components should be designed so that they are as airtight as possible. This requires an air barrier on both the inside and outside of the insulated portion of the wall.

Building envelope assemblies will tend to dry out and hence protect themselves from adverse affects of water incursions if water vapour transmission toward the cool dry side of the envelope is not impeded with a vapour retarder. In cold climates the envelope will dry toward the outside. In hot humid climates the envelope will dry to the air conditioned interior. In mixed climates the envelope will dry to the outside during the heating season and to the inside during the cooling season. The dynamics of water vapour movement through envelope assemblies is complex, especially in parts of the country that have both a heating and cooling season. For this reason it is prudent to verify the drying properties of an envelope construction by performing a hygrothermal simulation such as WUFI. (WUFI is a hygrothermal modelling program distributed by Oak Ridge National Laboratory ORNL. See references below.)

EMERGING ISSUES

CURRENT AND FUTURE RESEARCH AND DEVELOPMENT

There are no standard methods for analysis of mold samples. The American Society for Testing and Materials has recently formed a mold committee that is beginning the work of developing standards.

The health effects of mold and bacteria in the built environment are being studied at this time. It is known that allergic reactions can be caused by microbiological amplifications, and that there is an association between amplification and asthma. However, it is still clear if more serious health effects result from exposure to microbiological amplifications.

RELEVANT CODES AND STANDARDS

There are currently no federal codes or standards relative to mold and bacteria in buildings.

Maple Leaf Mold Inc. is a certified mold / asbestos removal and biological disinfection / air analysis company located in Toronto that uses certified IICRC technicians for all testing and remediation projects.

We are a professionally licensed firm experienced in testing, verifying and removing Mold / Asbestos / Lead and other environmental contaminants as well as providing disinfection services to control and kill biological contaminants.

Call 416-254-7256 to talk with us about your issue anytime.